All our leather products are handcrafted of goat, sheep or cow leather, animals entirely intended for human consumption without any cruelty.

MOROCCAN LEATHER | TANNING PROCESS

All Traditional Moroccan Leather Products are made using Full Grain Leather Hides.

These, aren't Industrially processed leather hides, unlike Italian, German and Spanish. Meaning that they haven't had the surface buffed or sanded to remove any imperfections and therefore, using all its original grain and natural scars, scratches and bites instead, producing a more natural-looking hide.

Full Grain Leather is very durable and as it ages, creates a gorgeous patina over time that gives to your product an unique character that we personally love!

Material

Cow Leather

Cowhide is the natural hide or skin of a cow. Cow leather, the most widely used leather, is actually processed cowhide.

Since beef is consumed all over the world, abundant raw skins are available for leather production , thus making cow leather affordable. About 65 to 70 percent of the world’s population produces cow leather which is used to make shoes , wallets, clothing such as jackets and belts, car seats, furniture upholstery, and saddles.

Cow leather is the most widely used leather and accounts for about 65 to 70% of world production. Cow leather is used for soles and uppers of shoes, for car seats and furniture upholstery, belts and straps, saddles, leather clothing and much more. There is hardly any area in which bovine leathers or calf skins are not processed.

Sheep leather

Sheepskin, sometimes also called as shearling is the sheep hide with fur. Without the fur, this skin is called sheep or lamb leather. When sheepskin is tanned (processed) in order to create sheepskin shearling, the fleece or fur is kept intact.

Considering its warmth and softness, sheepskin shearling leather is used for seating areas of chairs, and winter clothing such as jackets , gloves, caps. Furthermore, the fleece of lambskin is 100 percent protein, antibacterial by nature hence it can be used to protect wounded skin.

Lambskin or Sheep leather is the leather processed after its fleece or fur is removed from the hide which gets processed further to make wool fabric. So, lambskin leather would be the leather alone without its fur attached. Its the more common form of leather seen.

There are about 1.2 billion sheep and lambs in the world of which 15 to 25% are slaughtered annually. Sheep leather, lamb leather and lambskin are second behind cow leather with about 10% of world production. 90% of the sheep are woolly sheep. The finer and denser the wool, the thinner and worse the leather quality. Sheep leather is used for book covers, clothing, gloves, leather accessories and occasionally for furniture.

Sheep are raised for the production of wool. There are countless varieties of skin with considerable differences in skin quality. There can be considerable differences due to environmental conditions (climate, environment, food) even within the same breed.

Lamb leather

Lamb is the young of the sheep, up to a year old. The delicate meat of lamb is preferred to the flesh of adult animals.

Lamb leather is used for clothing. Its softness and lightness makes a smooth leather for leisure jackets, skirts, dresses or leather pants. Lambskin is also used for gloves, belts, purses, bags, hats or shoes. Particularly expensive leather clothing is often made of lambskin.

Goatskin - Goat leather

There are over 550 million goats in the world. 20 to 40% of these are slaughtered annually. Goat leather is ranked third in the world after cow leather and sheep leather with approximately 8 to 10% of world production.

Goats are found in many regions of the world. In contrast to sheepskin, goats do not have any grease deposits in the skin and are therefore more resistant but still supple and fine. Goat leather is therefore more valuable than sheep leather. It is lighter than many other leather types. It is usually tanned using a combination method and is relatively cheap. It is barely distinguishable from lamb leather.

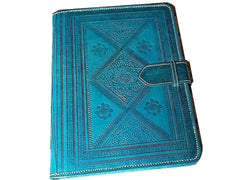

Leather of goats is used for the production of clothing, gloves, book covers, shoes or bags.

Maroquin leather - Maroquinerie

In the 16th century, Europe discovered goat leather from North Africa. They copied the tanning and dying method and called the leather after the country Morocco. Hence, the term "Maroquin leather".

Comparaison

- Cow hide is the thickest and toughest of all three, but is also the most rigid which makes it ideal for shoulder bags, rucksacks and shoes/sandals.

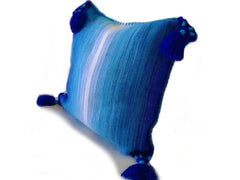

- Sheep hide is the softest of the three, making it ideal for delicate items like embodied purses and handbags, and much more including pouffes but any items that will see a lot of usage in their lifetimes (such as pouffes) are prone to tearing/ripping.

- Goat hide is a perfect balance of the other two. It is isn't as thick as cow, but is much tougher than sheep, and isn't as soft as sheep, but compared to cow is like a baby's bottom to sandpaper. Therefore, pouffes are generally made from goatskin, to be soft to the touch, yet durable enough to see you through many years of traditional leisure.

Leather preparation

Leather production is one of the most significant aspects of Moroccan craftsmanship. Production of leather hides happens in either Fez or Marrakesh, fully occupied by tanneries neighbourhoods.

Production is all achieved manually without the need of machineries, using only 100% natural resources and no artificial products or chemicals. A natural process performed since medieval times.

The tanneries are composed of numerous stone vessels filled with a vast range of dyes and various liquids spread out like a tray of watercolors. Dozens of men, many standing waist deep in dyes, work under the hot sun tending he hides that remain soaked in the vessels.

- Hides are first soaked during 2-3 days in a caustic mixture of cow urine, quicklime, water and salt, while tanners scrap away hair fibers and fat in order to prepare them for dyeing. This helps to break down the tough leather, loosen excess fat, flesh and hair that remain on them.

- After, they are soaked again in a set of vats containing a mixture of water and pigeon poo, that contains ammonia that acts as a softening agent that allow hides to become malleable so it is easier to work with them and they can absorb the dye.

-

Skins are then transferred to the becks where artisans trample them barefoot everyday from 6h to 14:30h to knead the hives and achieve the desired softness.

- When the skins are dry and smooth, then they are ready to be dyed. And to do this job, they use natural products that are exclusively used for dyeing: the poppy for red, mint for green, indigo for blue, kohl for black, henna for orange and a mixing oil with pomegranate for yellow.

- Hides thus, prepared for one week, are then rinsed and relaxed for one day by means of a wood machine in which they are rotated.

Leather Work

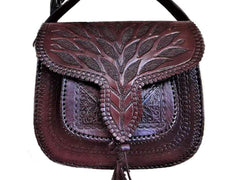

Leather bags

After being designed, every piece of leather is carefully cut and sewn using traditional tools, then oiled in order to remove the leather smell.

For decoration, we use engraving, painting and inlaying with colored leather, Barbarian kilim, Gemstones, copper or silver, depending on each design. You can find out more by visiting Moroccan Corridor Leather Bags gallery.

Leather Ottomans

The artisans begin by sketching out the designs, a process that has become practically second nature to them. After that, they dye the leather and begin drawing the patterns on it.

Following that, they cut and stitch each small piece of leather needed to make the patterns (which can be seen on the top and sides of the pouf) to the proper sizes, shapes, and colors. The entire pouf-making procedure takes at least 10 hours and requires at least two artisans.

Credits Section: